About Wencan

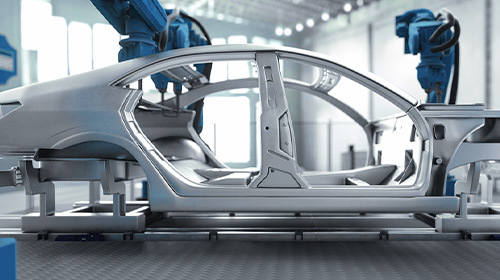

Wencan Group Co., Ltd. (stock code: 603348), listed on the Shanghai Stock Exchange in 2018, is a world-leading company engaged in the R&D and manufacturing for automotive aluminum alloy castings. Specializing in the R&D, manufacturing and sales of automotive aluminum alloy precision castings, Wencan offers a range of flexible and differentiated manufacturing solutions featuring high-pressure casting, low-pressure casting and gravity casting. Through material innovation and process advancement, Wencan is committed to providing global automotive customers with lightweight products of high security and reliability to be applied in body structural system, integrated body system, battery housing system, new energy power system, chassis system, brake system, engine and transmission systems, and other core components of new energy vehicles and traditional fuel vehicles, empowering the green transition of the automotive sector.

-

1998Year of Incorporation

-

6000 +Employees Worldwide

-

20 +Export Countries/Regions

-

3 +Aluminum Casting Processes

Dedicated to delivering more technologically innovative, lightweight, and highly reliable products to automotive customers all over the world

-

Body Structural System

-

Integrated Body System

-

Battery Housing System

-

New Energy Power System

-

Engine and Transmission Systems

Body Structural System

Integrated Body System

Battery Housing System

New Energy Power System

Engine and Transmission Systems

Innovation-Driven, Technology-Leading

Synergy across Asia, Europe, and the Americas;

Accumulation of advanced processes;

R&D of cutting-edge technologies;

Spearhead the effort to empower customers to innovate and succeed.

Intelligent Manufacturing

As a globally leading company engaged in R&D and manufacturing of automotive aluminum alloy castings, Wencan enjoys significant first-mover advantages in aluminum die casting of body structural system and integrated body system, and is the vanguard of aluminum alloy brake castings (master cylinders and calipers) worldwide. Wencan has accumulated profound experience in equipment customization, material R&D, mold design, process design, and application.

R&D & Innovation

Wencan Foundry Research Institute has independently designed and manufactured more than 30 sets of ultra-large die-casting molds for die-casting machines (6,000T or above). We developed Non-Heat Treatable (NHT) materials pioneering in performance in cooperation with our vendors, which underpin the superior performance of integrated body parts. For large castings processing, we innovatively developed a number of integrated intelligent drilling and milling machining production lines, bringing the manufacturing of large integrated body parts to complete automation and ensuring the manufacturing efficiency of products.

Sustainable Development

We actively respond to the national goals of “Carbon Peak and Carbon Neutrality” and the requirement of “dual energy consumption control”, by developing in a “low-carbon, digital, integrated, and intelligent” way and deepening interconnection and collaboration with our long-term partners in the “process chain, supply chain, industry chain, and innovation chain”.

News & Information

Read More