Wencan Foundry Research Institute

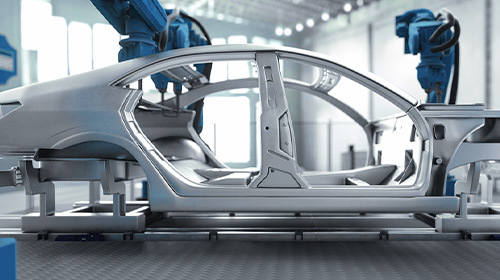

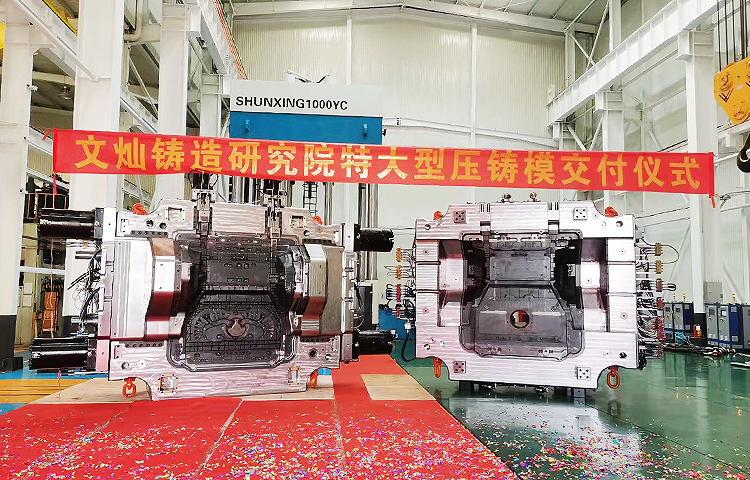

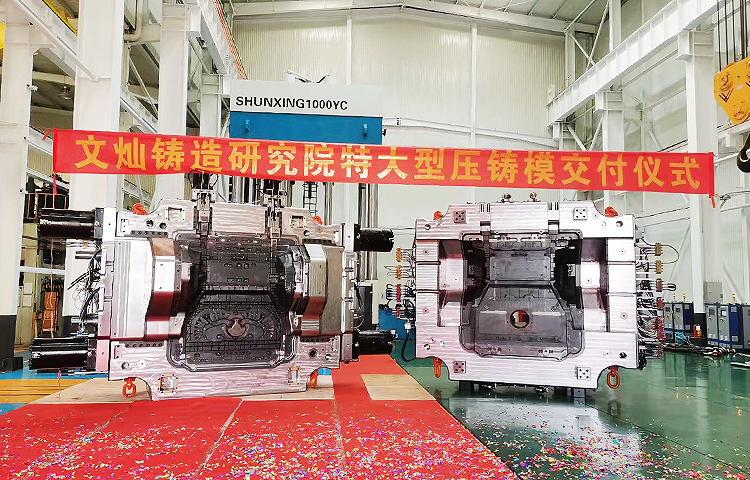

Wencan Foundry Research Institute synergizes Wencan’s overall technical R&D and mold manufacturing. It successfully developed the largest integrated rear floor assembly in the die-casting industry, which was awarded the “2023 Excellence in Structural Aluminum Die Casting” by the North American Die Casting Association (NADCA) and has achieved bulk supply to leading NEV manufacturers, with a yield rate of 95% and higher, driving a transformative shift in NEV manufacturing by virtue of its stable and efficient mega-casting mold technology. With its predecessor founded in 1998, operated as a subsidiary of Wencan in 2014 and name change in 2023, Wencan Foundry Research Institute has over 20 years of R&D experience, and is now ranked “Top 20 Most Competitive Die-Casting Mold Enterprises in China” and “Top 20 Die-Casting Mold Manufacturers in China”. Focusing on high-precision and cutting-edge products, Wencan has fostered strong collaborations with upstream and downstream strategic partners to deepen cooperation in custom equipment development, material R&D, mold design, process optimization, and applications, thus driving sustainable progress across the industry.

Expanded in 2014, Wencan Foundry Research Institute has over 20 years’ experience.

20+ years of experience

R&D personnel at Wencan Foundry Research Institute

Number of patents

Wencan Foundry Research Institute holds high-vacuum die-casting technology, digital simulation analysis technology and other internationally advanced technologies

Maximum tonnage die-casting machine compatible with the mega molds developed by Wencan Wencan Foundry Research Institute

Annual mold output of Wencan Foundry Research Institute

R&D Capabilities

-

01

Product Design & Optimization Capability

With its internationally leading technical capabilities in mold flow analysis, mold temperature control, and high-vacuum technology, Wencan is able to rapidly respond to new demands from NEV automakers and support their synchronized development, providing superior product design and optimization services to help customers accelerate innovation, and is highly praised by customers for its product capabilities.

Analysis Software: MAGMA, JSCAST

Design Software: CATIA, Pro/E, UG

-

02

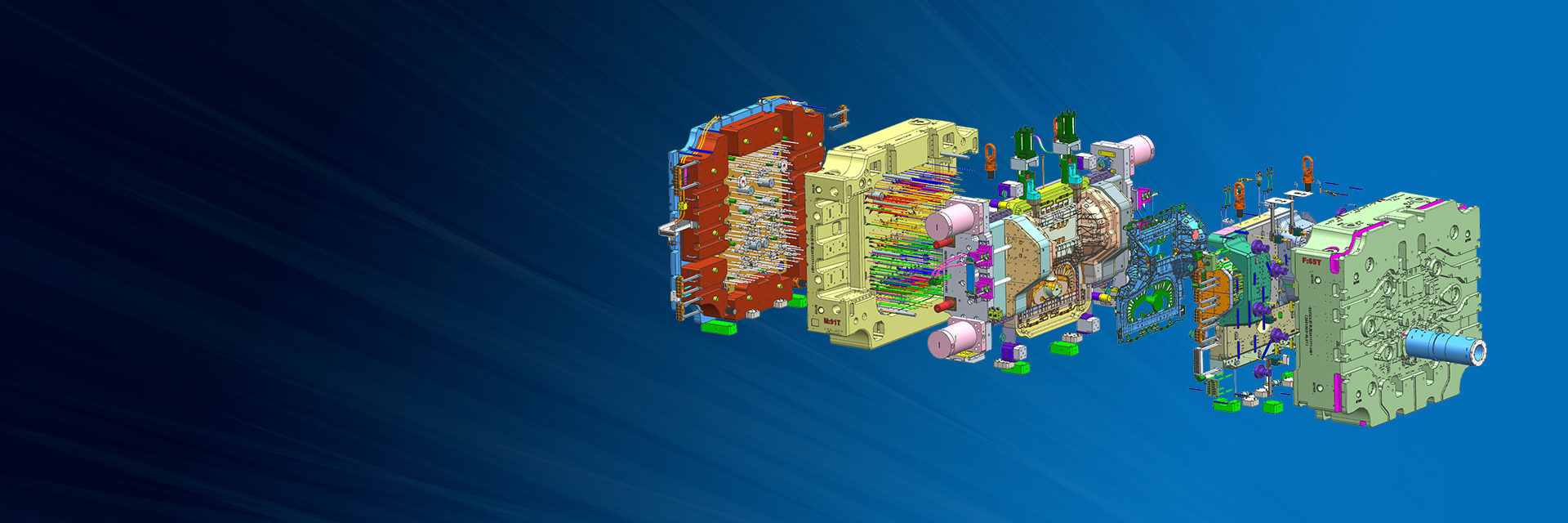

High-End Mold Design & Manufacturing Capability

Wencan Foundry Research Institute has established a comprehensive standardization system and technical specifications for mold manufacturing, backed by extensive experience. In recent years, Wencan Foundry Research Institute has designed and manufactured over 200 sets of body structural component molds, including approximately 30 sets of mega die-casting molds for die-casting machines above 6,000T.

-

03

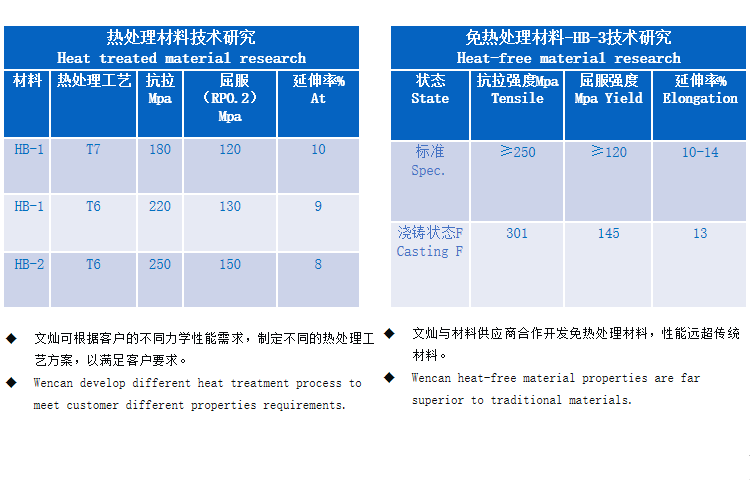

Materials Development and Fabrication Capability

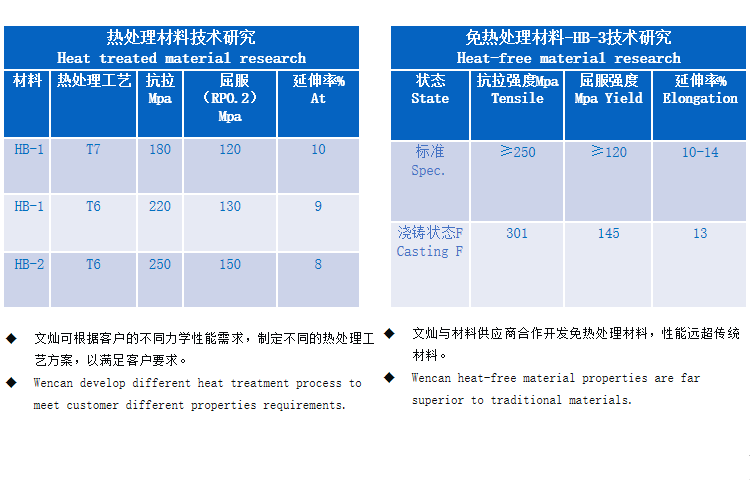

Wencan has participated in the project of Preparation and Processing Technology and Application of High Performance Aluminum Matrix Composites and Large Components under the program of Preparation and Processing Technology of Particle Reinforced Metal Matrix Composites and Components, a National High Technology Research and Development Programs of China (863 Program).

—— Body Structural Members play a supporting and impact-resistant role for the automobile. Their quality is directly related to the quality of the body's bearing capacity. Therefore, they have extremely high requirements for strength, elongation, and weldability. After many years of R&D and production experience accumulation, Wencan has mastered the preparation technology of aluminum alloy materials for body structural components, and has started to supply customers with aluminum alloy body structural components in bulk.

—— Wencan has developed Non-Heat Treatable (NHT) materials pioneering in performance in cooperation with our suppliers, which underpin the superior performance of our integrated body parts.

—— However, for certain automotive parts requiring so high abrasive resistance that general aluminum alloy castings are difficult to meet in terms of abrasive resistance and hardness, Wencan has, through research and development of new materials and new processes, developed aluminum alloy materials and supporting die-casting technologies that can replace cast steel products, and has mass-produced and supplied relevant products for and to the major automotive gearbox manufacturers in the world.

R&D Team

Wencan Group has established the Foshan Wencan Engineering Technology Research Center for Precision Die Casting Molds, the Enterprise Technology Center of Jiangsu Province, the Postdoctoral Innovation Practice Base of Jiangsu Province, the Enterprise Technology Center of Tianjin, and the Wuxi Engineering Technology Research Center for NEV Lightweight Components, and built an R&D team of over 600 researchers, to devote itself to the research on new material development, precision die casting, and finish machining technologies and processes. In recent years, the Group has developed new technologies including numerical simulation of gas-liquid multiphase flow in the die-casting filling process, slow-pressure injection die-casting, and 3D tomographic scanning of die casting micro-holes. Leveraging Wencan's strong R&D capabilities, several subsidiaries have won National Machinery Industry Science and Technology Awards (Second Prize for Technological Invention & Third Prize for Scientific and Technological Progress) and Third Prize for Provincial-level Science and Technology Award.

In addition to leveraging its own R&D capabilities, Wencan Group has further enhanced its independent R&D and technological innovation capabilities through cooperative development and technical exchanges with auto makers such as Mercedes-Benz, Volkswagen, Seres, NIO, and Li Auto. Besides, Wencan Group has formed a system and mechanism combining internal and external R&D innovation by in-depth cooperation with Tsinghua University, South China University of Technology, Shanghai Jiao Tong University, Southeast University and other universities and colleges.